MALT WHISKY PRODUCTION

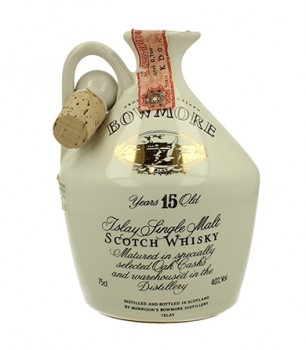

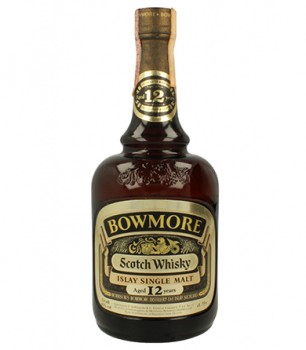

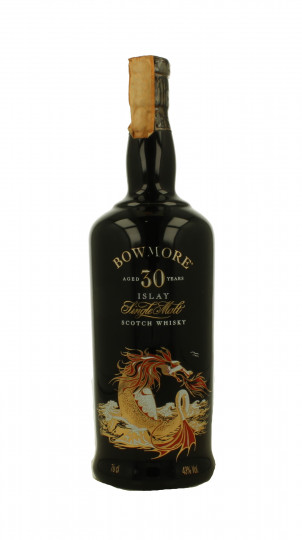

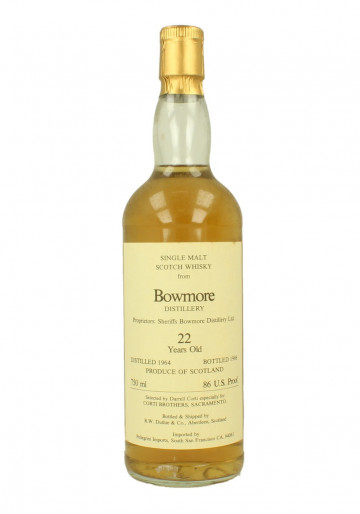

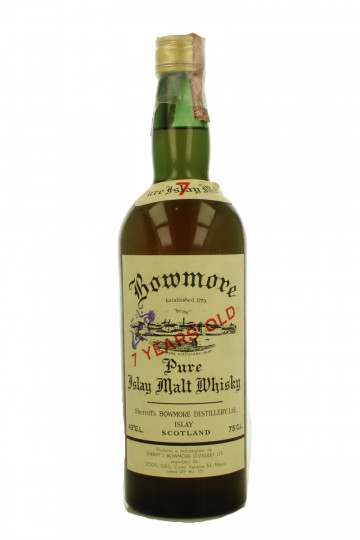

Floor malting, the traditional method of malting barley, was usual at malt whisky distilleries in Scotland, but is now limited to the Balvenie, Bowmore, Laphroaig, Highland Park, Kilchoman and Springbank.

The first stage is placing barley in steeps, adding water and draining at regular intervals, giving sometimes the barley “air rests” to avoid drowning. A typical cycle is ten hours’ submersion, followed by four hours’ air rest, then submersion.

The barley is then spread out in a shallow layer on the malting floor. Barley germinates over four to five days, which creates heat that increases temperature. Heat is dissipated by turning the barley- One way of doing this is with a malt shield, digging up underlying layers of barley and scattering them on the surface.

Turning ensures that all the barley experiences the same conditions and germinates at the same rate. Another practical advantage is that turning the barley stops the emerging rootlets from matting together.

A traditional test to check the barley’s progress is to rub a grain between the finger and thumb. If this produces a smooth past, it’s time to start kilning.

Commercial maltings have played a central role in Scotland since the 1960s and 1970s, when many malt whisky distilleries closed their floor maltings. Distilleries now typically have supply contracts with commercial maltings, specifying the barley variety, quantities and delivery dates, to ensure a consistent supply. After all, without barley there would be no malt whisky.

The malting process begins with steeping. This takes around 48 hours, during which barley is submerged in water for several hours, then the water is drained to allow the barley an “air rest” for a few hours, before adding fresh water and repeating the process.

This can take place in a saladin box, a method developed in the late 19th century. Turning the barley is vital, to prevent the roots intertwining.

In order to start growing, the barley requires an energy source, which is starch. Barley contains numerous “packets” of starch enclosed by cell walls, and during germination the walls begin breaking down to provide access to the starch.

This is the stage at which barley meets a distiller’s requirements. To prevent it from growing further, which would use up more starch, it is dried using hot air from a kiln for one or two days.

The entire malting process, including peating, can be automated using a SGKV (Steeping Germination Kilning Vessel), which resembles a washing machine with a detailed cycle.

Source: The Whisky Dictionary: an A-Z of Whisky, from history & heritage to-distilling & drinking